SLATES & QUARTZITES

SLATES AND QUARTZIES –

What is Slate?

Slate is a fine-grained homogeneous sedimentary rock composed of clay or volcanic ash which has been metamorphosed (foliated) in layers (bedded deposits). Slate can be made into roofing shingles (‘roofing slates’ in the UK ) because it has two lines of breakability: cleavage and grain. This makes it possible to split slate into thin sheets.

Slate is a fine-grained homogeneous sedimentary rock composed of clay or volcanic ash which has been metamorphosed (foliated) in layers (bedded deposits). Slate can be made into roofing shingles (‘roofing slates’ in the UK ) because it has two lines of breakability: cleavage and grain. This makes it possible to split slate into thin sheets.

When choosing roofing materials, one must take into consideration the longevity of the roofing material, as well as the installation cost. Slate roofs have been known to last hundreds of years in comparison to the synthetic roof which typically lasts 10-20 years. Synthetic and manufactured roofing materials may initially save money at the time of installation, but the slate roof will last many lifetimes, making it the more permanent, economical choice.

What is Quartzite?

Quartzite is a hard, metamorphic rock which was originally sandstone. Through heating and pressure usually related to tectonic compression within orogenic belts, the original quartz sand grains and quartz silica cement were fused into one. Pure quartzite is usually white to grey. Quartzites often occur in various shades of pink and red due to varying amounts of iron oxide. Other colors are due to impurities of minor amounts of other minerals.

Quartzite is a hard, metamorphic rock which was originally sandstone. Through heating and pressure usually related to tectonic compression within orogenic belts, the original quartz sand grains and quartz silica cement were fused into one. Pure quartzite is usually white to grey. Quartzites often occur in various shades of pink and red due to varying amounts of iron oxide. Other colors are due to impurities of minor amounts of other minerals.

Orthoquartzite is a very pure quartz sandstone composed of usually well rounded quartz grains cemented by silica. Orthoquartzite is often 99% SiO2 with only very minor amounts of iron oxide and trace resistant minerals such as zircon, rutile and magnetite. Although few fossils are normally present the original texture and sedimentary structures are preserved.

In true metamorphic quartzite, also called meta-quartzite, the individual quartz grains have recrystalized along with the former cementing material to form an interlocking mosaic of quartz crystals. Minor amounts of former cementing materials, iron oxide, carbonate and clay, are often recrystalized and have migrated under the pressure to form streaks and lenses within the quartzite. Virtually all original textures and structure have usually been erased by the metamorphism.

Quartzite is very resistant to chemical weathering and often forms ridges and resistant hilltops. The nearly pure silica content of the rock provides little to form soil from and therefor the quartzite ridges are often bare or covered only with a very thin soil and little vegetation.

Because of its hardness (about 7 on Mohs’ scale of mineral hardness), crushed quartzite is often used as railway ballast.

Standard sizes are:

Tiles:

Sizes Thickness

300x300mm, 300x200mm, 400x200mm,

400x400mm, 300x600mm, 600x600mm in 10-14 mm

300×300 should be considered as 1’x1′

NATURAL TILES WILL BE IN A THICKNESS OF 10-14mm

GAUGED TILES WILL BE IN A THICKNESS OF 10mm +/-1mm

NATURAL TILES TO BE PACKED IN EXPORT IN WORTHY WOODEN CRATES

GAUGED TILES TO BE PACKED IN CORRUGATED BOXES AND THEN INTO WOODEN PALLETS.

SLABS:

RANDOM SIZES AVAILABLE IN 20mm AND 30mm THICKNESS

PRICES FOR RANDOM ARE ON A CRATE BASIS.

Parameters definition:

Polished – generally gloss levels should be 0-8 as measured by a gloss meter.

To achieve this, final polishing should have been done by italian machines.

Honed: To grind a surface with a high grit material to a uniform specification without producing a reflective surface

Calibration: To grind a surface with a high grit material to a uniform surface to maintain the thickness variation.

Shade variation – Slabs / tiles should be sorted to ensure uniformity of shade. Normally, any colour can be sorted into three shades. Sorting is simple -just lay all the material on the floor and look from different directions.

Colour patches – These are darker or lighter patches or bands of single colours due to mineral localisation.

Free lengths: i.e. lengths varying randomly while width is constant are also very attractive. Choose the widths as per the expected floor area. Buy random lengths and cut at your site to fit.

Flatness Tolerances

A 4’ dimension in any direction on the surface shall determine variation from true plane, or flat surfaces. Such variations on polish, hone, and fine rubbed surfaces shall not exceed tolerances listed below or 1/3 of the specified joint width, whichever is greater. On surfaces having other finishes, the maximum variation from true plane shall not exceed the tolerance listed below or + 3 mm of the specified joint width, whichever is greater.

Polished, honed or fine rubbed finishes… +/- 1 mm

Sawn, Calibrated, 4-cut and 6-cut…. +/- 1 mm

Split face, pointed or other rough cut finishes… +/- 1mm

Edges also can be chamfered / bevelled. Chamfering removes whiteness and chipped edges. This looks very good. Chamfering is a simple process in which a polishing brick is run at an angle of 45 °.

DIAGONAL OUT

DIAGONAL OUT MUST NOT BE MORE THAN 1MM FOR TILES. IN SLABS IT VARIES.

Quality Parameters:

One side natural and one side calibrated

a. One side Calibrated.

b. Other side natural.

c. Thickness variation is +/- 1mm

One side natural and one side honed

a. Honed finished one side.

b. Other side natural.

c. Thickness variation is +/- 1mm

One side Calibrated and one side honed

a. Honed finished one side.

b. Calibration on the other side.

c. Thickness variation is +/- 1mm

One side Calibrated and one side mirror polished

a. One Side Fine Mirror Polished.

b. Calibration / Honed on the other side.

c. Thickness variation is +/- 1mm.

One side Calibrated and one side fine mirror polished( with max. gloss)

a. One Side Fine Mirror Polished.

b. Calibration / Honed on the other side.

c. Thickness variation is +/- 1mm including all corner of the stone.

Note: The above Thickness variation mentioned is for the container at total. The variation in tile is not acceptable.

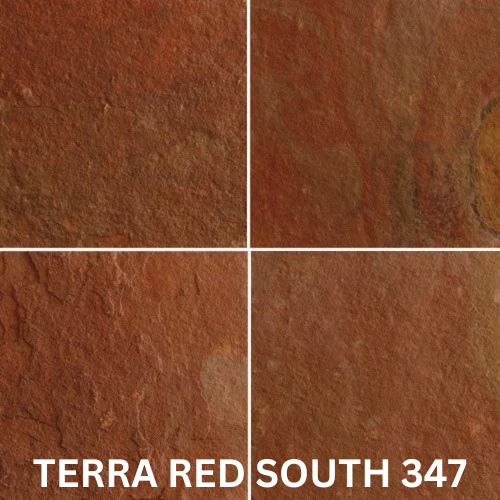

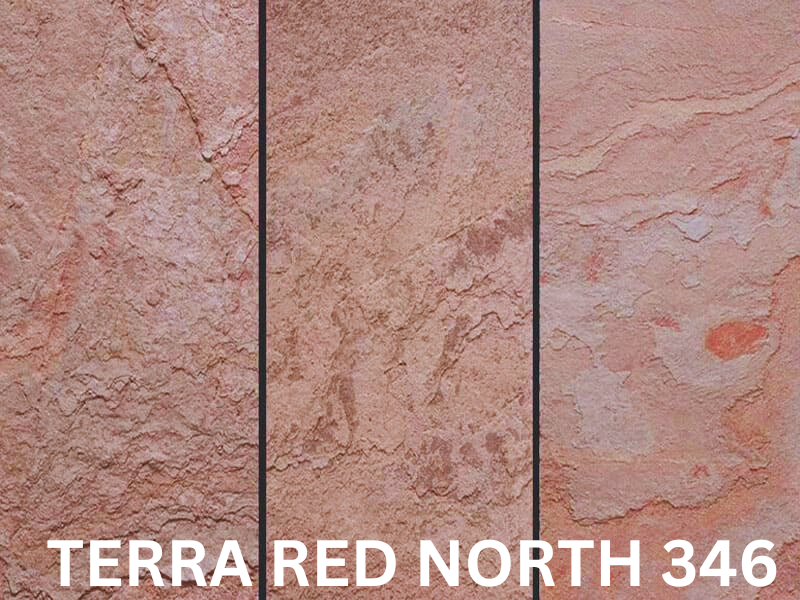

SLATE

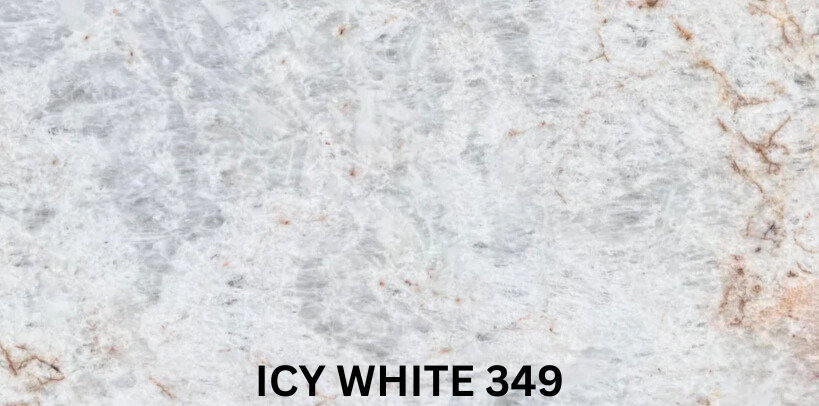

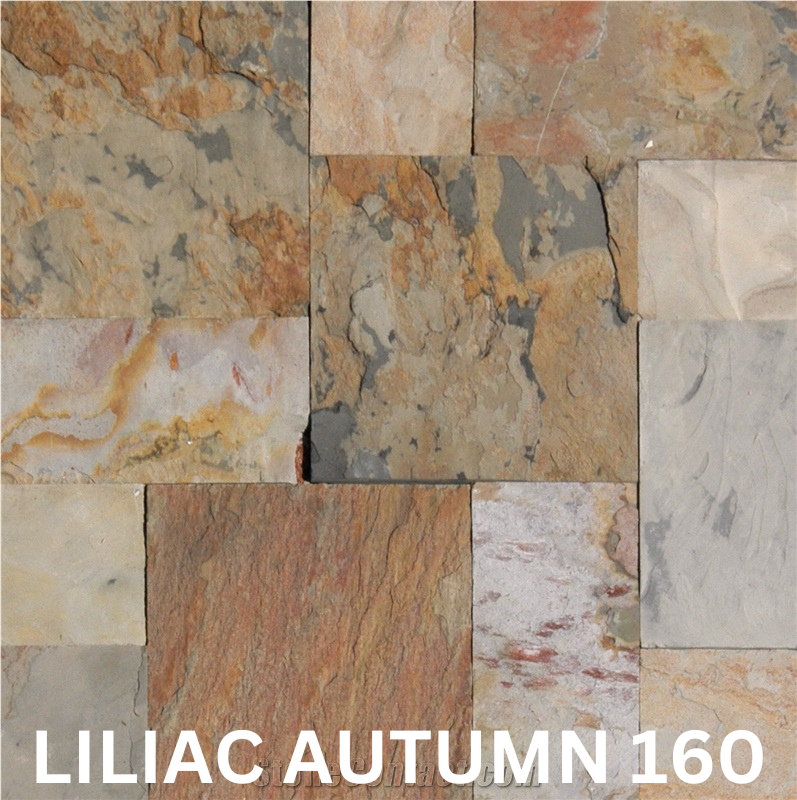

List of Products available & Photo Gallery

NOTE:The images shown in the picture gallery may have variations in color, texture, and design compared to the actual products.

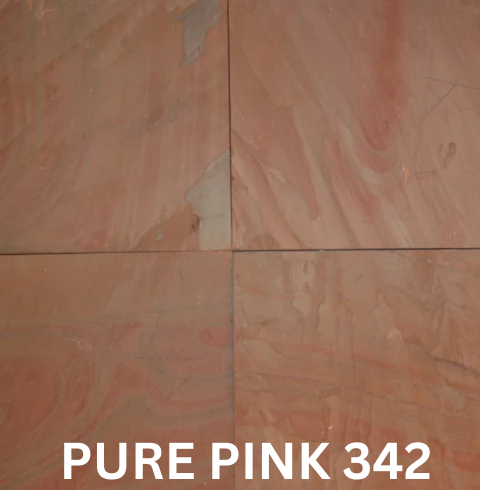

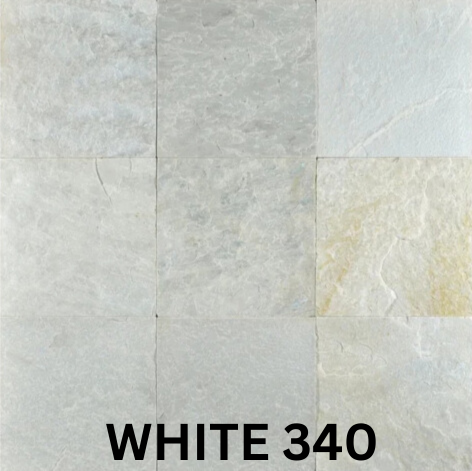

QUARTZITE

List of Products available & Photo Gallery