GRANITE

What is Granite?

Granite is a common and widely-occurring group of intrusive felsic igneous rocks that form at great depths and pressures under continents. Granite consists of orthoclase and plagioclase feldspars, quartz, hornblende, biotite, muscovite and minor accessory minerals such as magnetite, garnet, zircon and apatite. Rarely, a pyroxene is present. Ordinary granite always carries a small amount of plagioclase, but when this is absent the rock is referred to as alkali granite. An increasing proportion of plagioclase feldspar causes granite to pass into granodiorite. A rock consisting of equal proportions of orthoclase and plagioclase plus quartz may be considered a quartz monzonite. A granite containing both muscovite and biotite micas is called a binary granite. The average density is 2.75 g/cm3 with a range of 1.74 to 2.80.

The word granite comes from the Latin granum, a grain, in reference to the coarse-grained structure of such a crystalline rock.

Occurrence of granite

Granite occurs as relatively small, less than 100 km2 stock-like masses and as large batholiths often associated with orogenic mountain ranges and is frequently of great extent. Small dikes of granitic composition called aplites are associated with granite margins. In some locations very coarse-grained pegmatite masses occur with granite. Granite has been intruded into the crust of the Earth during all geologic periods, except perhaps the most recent; much of it is of Precambrian age. Granite is widely distributed throughout the continental crust of the Earth and is the most abundant basement rock that underlies the relatively thin sedimentary rock veneer of the continents.

Origin of granite

There are two theories for the origin of granite. The magmatic theory states that granite is derived by the crystal fractionation of magma. Thus granite bodies are the result of intrusion of liquid magma into the existing rocks. The granitization theory states that granite is formed in place by extreme metamorphism. There is evidence to support both theories, and both are useful to explain different observed features. The two may actually merge: as metamorphic conditions increase to the melting point of the metamorphosed granite, it will melt and become a liquid magma.

Uses of granite

Granite has been extensively used a dimension stone and as flooring tiles in public and commercial buildings and monuments.

Granite Slab Production

There are two types of slabs gang saw slabs and vertical slabs. Here the process is different from that of the tile unit. Here too the blocks are dressed with wire saws before they go on to a trolley for processing at the gang saws. Though we spend a little extra money on this procedure this ensures the optimum utilization of the cutting style in the gang saws and gives us an average recovery of about 30 to 31 sq meters for every cubic meter of each block

Granite Tiles Production

The factories from which we bring you the stone, all have state of the art facilities and machines that are the best of their kind anywhere in the world. Once the trailers carrying the stone arrive at the factory, the huge blocks are lifted and dressed. Then the blocks go to the block cutter for processing tiles where vertical and horizontal cuts are made literally slicing the blocks into slabs of the required thickness. These are now sent for calibration. This machine grinds away at the surface of the stone to make the thickness even.

Standard sizes are:

Tiles:

Sizes Thickness

SIZES OF 12′ X 12′,18′ X 18′ IN 10MM THICKNESS.

Slabs:

Sizes Thickness

RANDOM SIZES ARE AVAILABLE IN 20MM & 30MM THICKNESS.

| GRANITE (TILES) TILES TO BE PACKED IN THERMOCOLE BOXES & THEN WOODEN CRATES. “+/-“0.5 MM VARIATION IN THICKNESS. THICKNESS VARIATION IS +/-1MM |

Parameters definition:

Polished – To smooth or brighten a surface increasing the reflective quality and luster by chemical or physical processes. Generally gloss levels should be + 90 as measured by a gloss meter. To achieve this, final polishing should have been done by latest Italian/ French machines using imported abrasives.

Buffing: Using a non-abrasive pad attached to a machine, which rotates the pad in a circular fashion over the stone, generally between 150-300 RPM. Polishing formulations containing micro-fine abrasive materials are used with buffing to produce a more reflective gloss on the surface of stone. Waxes are also used with buffing to enhance the gloss of polished stone.

Honed: To grind a surface with a high grit material to a uniform specification without producing a reflective surface.

Sawn – i.e. unpolished. It is not advisable to buy this way because : floor polishers do not give as good a polish as factory machine polishers. many defects are not visible easily before polishing.

Calibration: To grind a surface with a high grit material to a uniform surface to maintain the thickness variation.

Gangsaw: To grind two sides of the stone surfaces with a high grit material to a uniform specification without producing a reflective surface.

Shade variation – Slabs / tiles should be sorted to ensure uniformity of shade. Normally, any colour can be sorted into three shades. Sorting is simple -just lay all the material on the floor and look from different directions.

Colour patches – These are darker or lighter patches or bands of single colours due to mineral localisation.

Scratches: The marring of the surface caused by physical trauma such as small stones or sand embedded in shoes scraping across a marble floor.

Staining: The absorption of foreign pigments or oils into the porous stone causing discoloration.

Double color – Sometimes two different grain sizes occur in the same slab, giving the appearance of a double colour.

Free lengths: i.e. lengths varying randomly while width is constant are also very attractive. Choose the widths as per the expected floor area. Buy random lengths and cut at your site to fit.

Flatness Tolerances

A 4’ dimension in any direction on the surface shall determine variation from true plane, or flat surfaces. Such variations on polish, hone, and fine rubbed surfaces shall not exceed tolerances listed below or 1/3 of the specified joint width, whichever is greater. On surfaces having other finishes, the maximum variation from true plane shall not exceed the tolerance listed below or + 3 mm of the specified joint width, whichever is greater.

Polished, honed or fine rubbed finishes… + 0.5 mm

Sawn, Calibrated, 4-cut and 6-cut…. + 1 mm

Edges also can be chamfered / bevelled. Chamfering removes whiteness and chipped edges. This looks very good. Chamfering is a simple process in which a polishing brick is run at an angle of 45 ?.

Quality Details:

Polished Granite

a. One Side Fine Mirror Polished.

b. Gangsawn/Cutter side

c. Thickness variation is + 0.5 mm to 1 mm depending upon Tile/Slab.

FINISHES

The stone is available in a range of eight smooth and textured finishes:

WATERJET: a non-slip matt finish, produced by working the surface of the stone with high-pressure water jets

HONED: a smooth finish with a slight sheen, produced by using a polishing head.

SANDED: sawn stone slabs are coarsely polished: this removes saw marks and leaves a semi-smooth, regular finish.

CLEFT: with this traditional treatment the stone is riven along its line of cleavage to reveal the natural grain; this gives an undulating surface with great character.

GRITBLASTED: a high-pressure airline projects coarse-grained grit onto the top surface of the stone producing a finish similar to cleft, but available on slabs of greater size.

FLAMED: the top surface of the slab is burnt off, giving an irregular textured

FINISHTEXTURED: the top surfaces of sawn slabs are pneumatically tooled to produce a pitted or grooved surface.

We are continually developing the range of finishes and can supply sample cards showing all materials and finishes. If you require a specialised effect we will be happy to discuss with you how it can be achieved.

PACKING

TILES ARE PACKED IN THERMOCOLE BOXES AND ARE FURTHER PACKED INTO WOODEN CRATE.SLABS ARE ALSO PACKED INTO WOODEN CRATES. POLYTHENE WRAPPER IS MADE TO COVER THE ENTIRE MATERIAL INSIDE THE WOODEN CRATE. FOR RANDOM SLABS, EACH SLAB IS PACKED IN A SEPARATE POLYTHENE WRAPPER, TO REDUCE OR TO AVOID SCRATCHING OF TILES AND SLABS WHICH ARE PACKED FACE TO FACE.

LIST OF PRODUCTS AVAILABLE PHOTO GALLERY

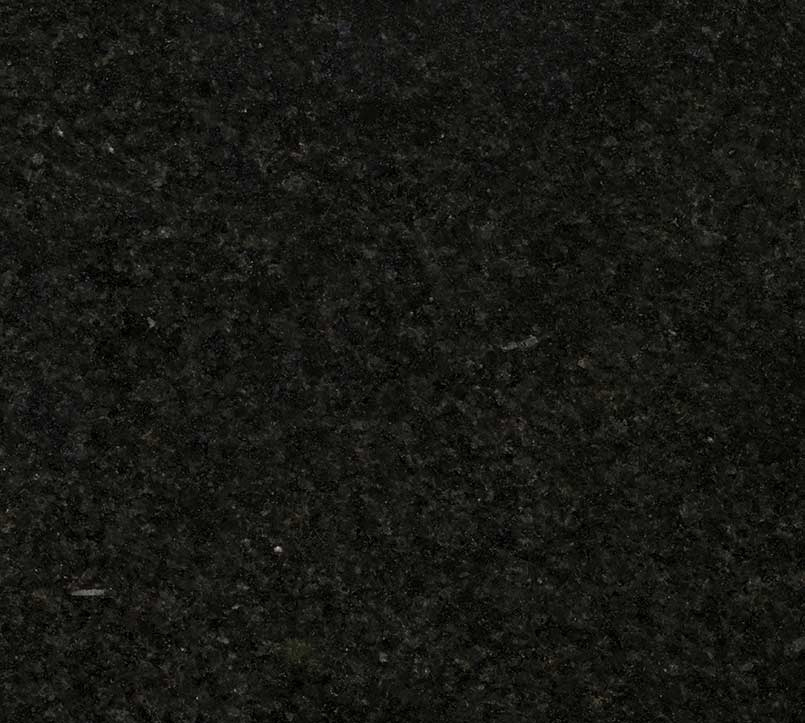

BLACK GALAXY

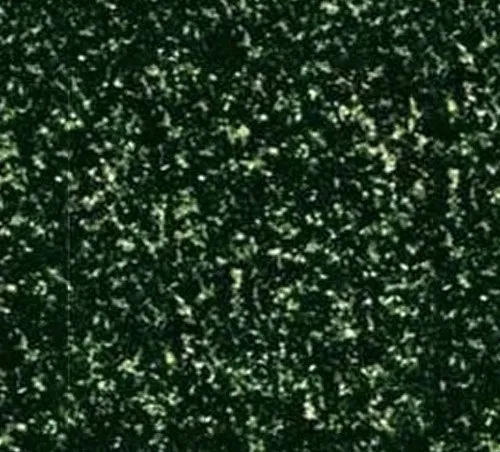

FOREST GREEN

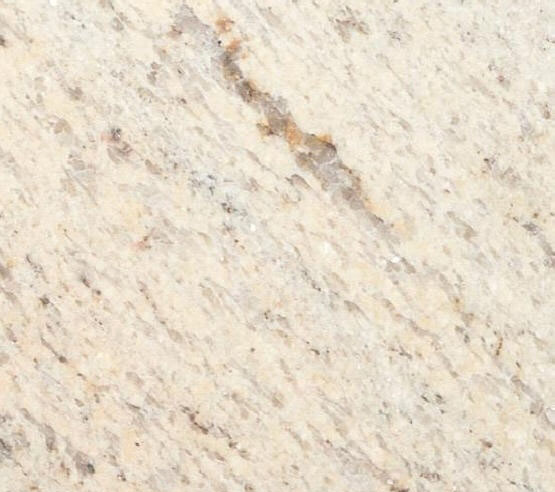

IMPERIAL WHITE

SAPPHIRE BLUE

SILVER PEARL

VYARA GOLD

ROYAL GOLD

COPPER SILK

ABSOLUTE BLACK

AMBER FANTASY

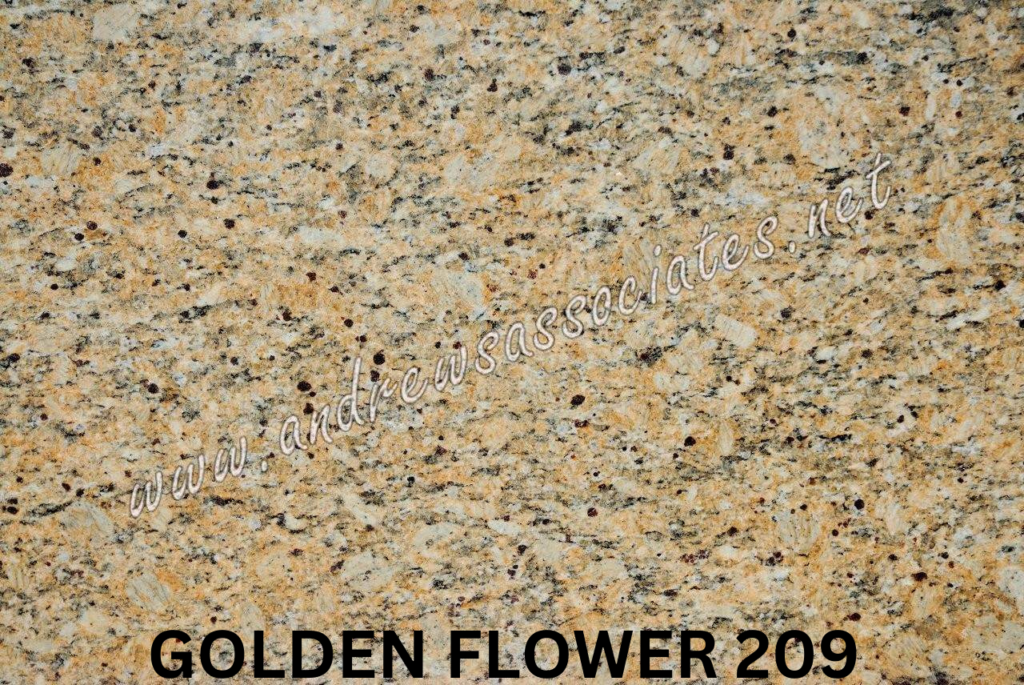

GOLDEN FLOWER

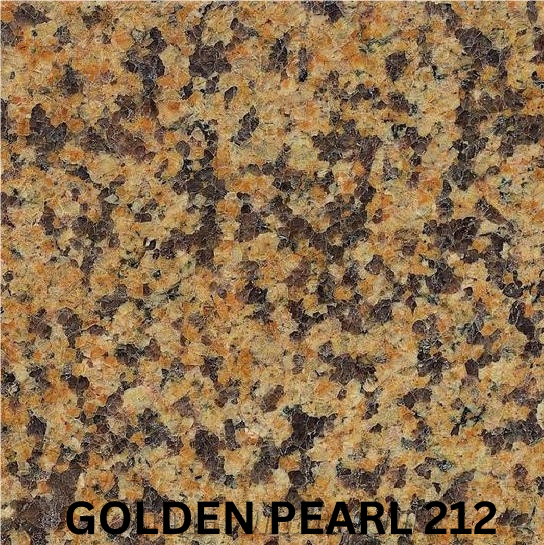

GOLDEN PEARL

JUPRANA DARK

MADURAI GOLD

MERRY GOLD

MULTICOLOUR NORTH

NEW IMPERIAL RED

PLATINUM WHITE

RAW SILK IVORY

TAWAB PINK

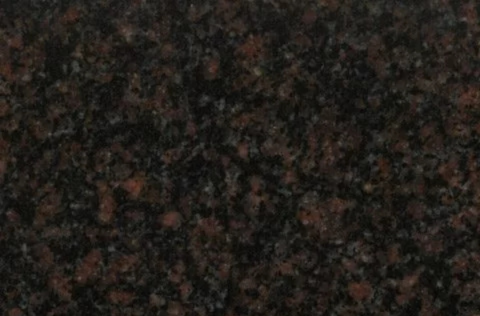

DESERT BROWN

HASSAN GREEN

INDIAN MOHGANY

SAPPHIRE BROWN

TAN BROWN

VIJAG BLUE

ROYAL CREAM

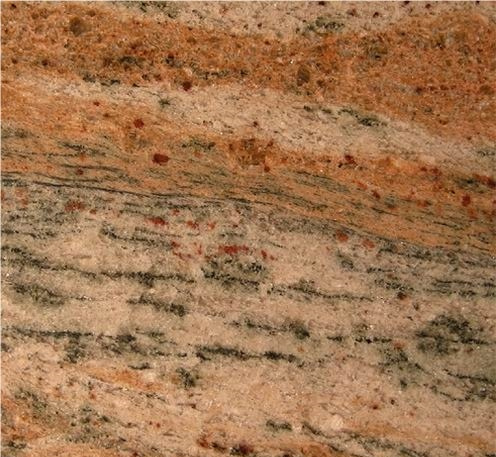

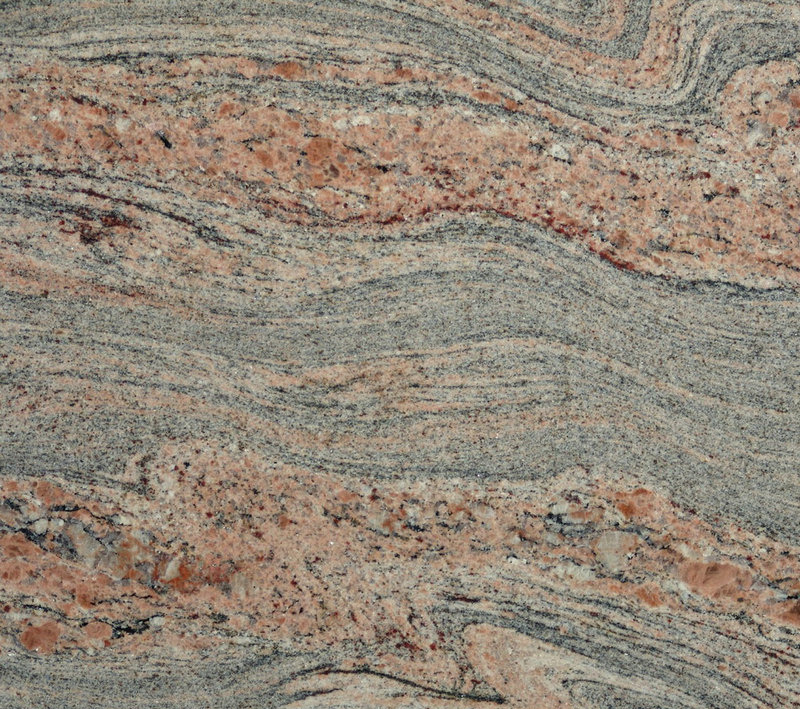

COLOMBO JUPRANA

COLONIAL DREAM

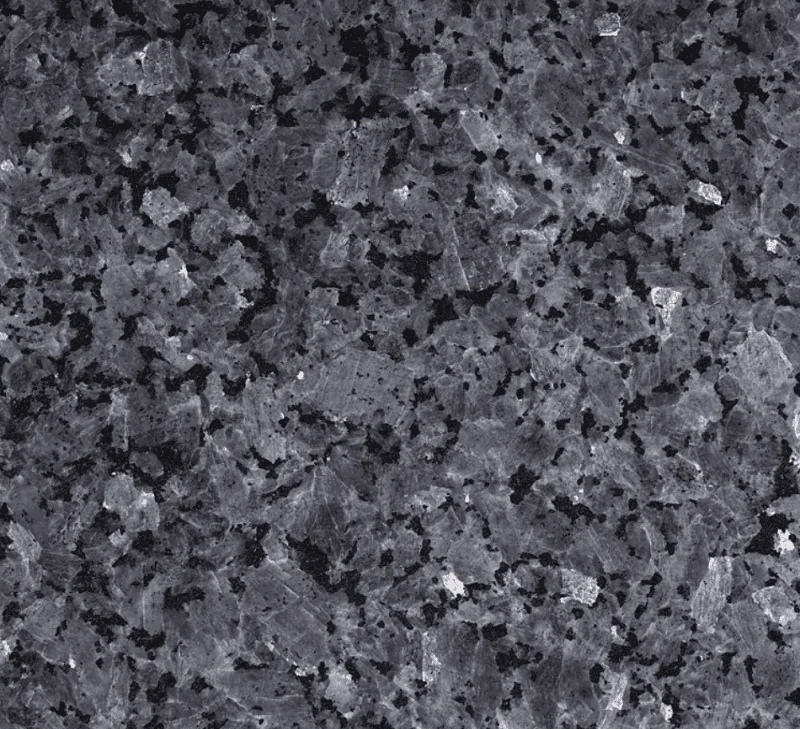

BLACK PEARL

GOLDEN OAK

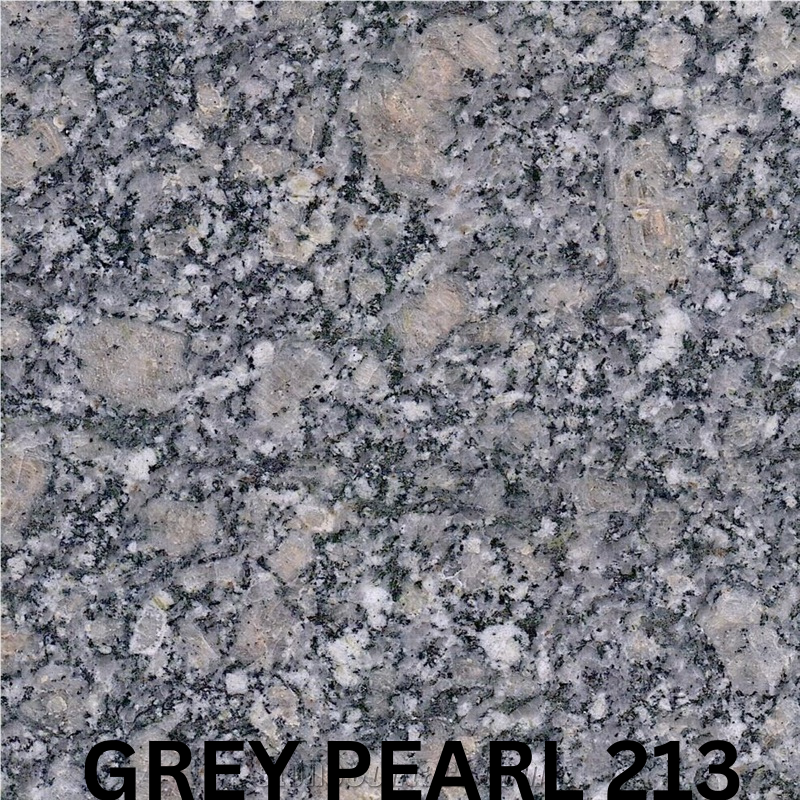

GREY PEARL

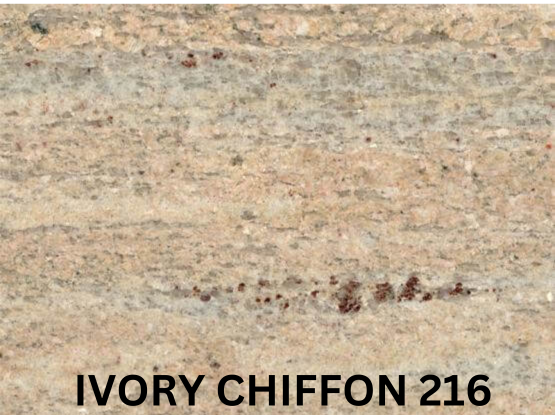

IVORY CHIFFON

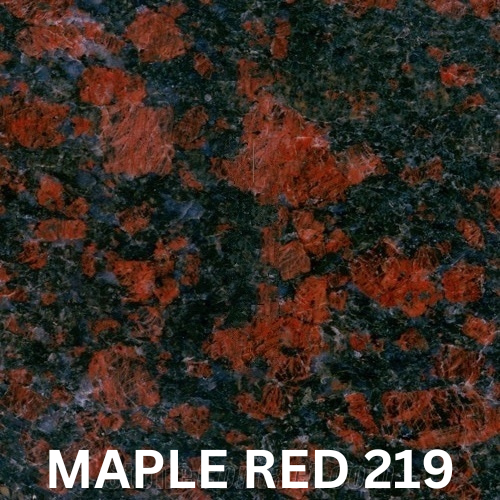

MAPLE RED

MOKALSAR GREEN

MULTICOLOUR

ORISSA BLUE

RAKHI GREEN

RAYMOND BLUE

VERDE MARINA

GHIBLI

HIMALYAN BLUE

PARADISO CLASSICO

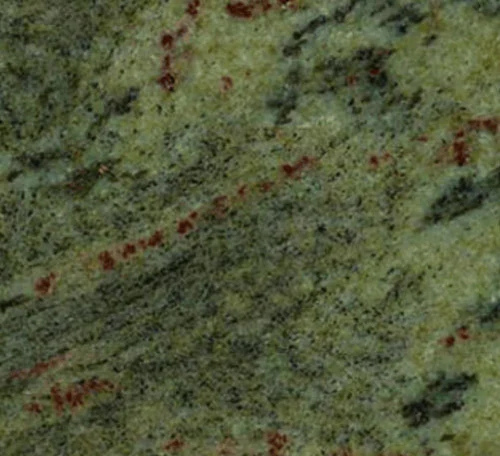

SEWEAD GREEN

TROPICAL GREEN

RUBY RED

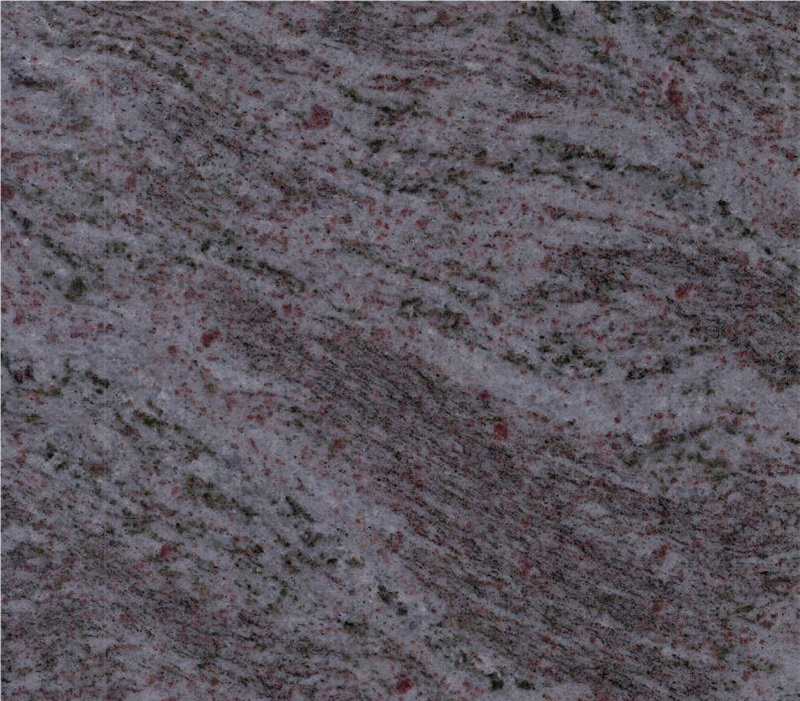

ROSY PINK

TIGER SKIN

SIRA GREY

BLUE STAR

GOLDEN YELLOW

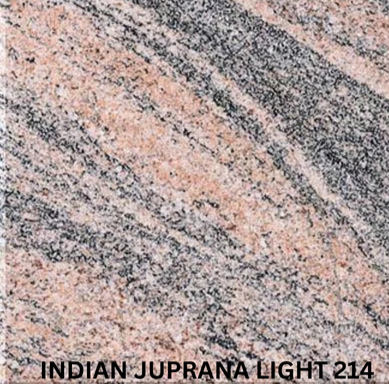

JUPRANA LIGHT

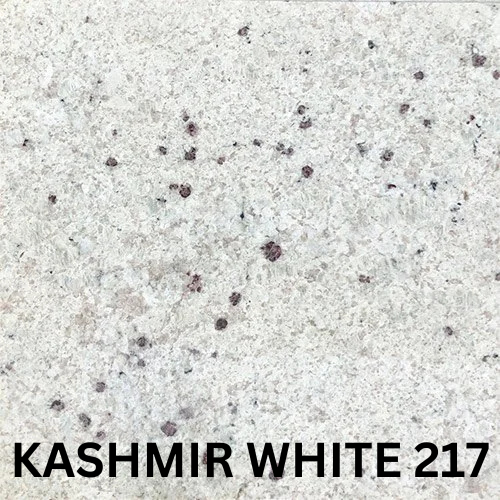

KASHMIR WHITE

MEDIUM BLACK

MULTICOLOUR RED

NAGEENA GREEN

PARADISO BASH

RAW SILK

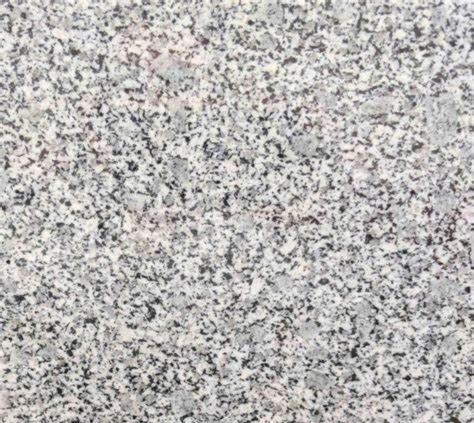

SALT N PEPPER